Milk cooling affects milk quality: the faster the milk is cooled after milking, the better its quality when it is collected from the farm.

Choosing the right cooling system for your farm is important, says DairyNZ, which lists some of the options available to farmers.

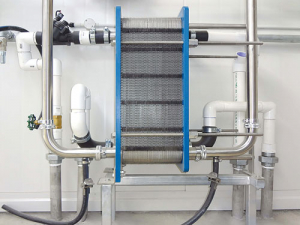

Plate heat exchangers

Plate heat exchangers (PHE) are a highly cost-effective means of cooling milk. A PHE consists of a series of very thin stainless steel plates. Water flows along one side of each plate while milk flows along the other. Heat is transferred from the milk to the water via the plate. The capacity of a plate cooler is adjusted by adding or subtracting plates.

Cooling towers

Cooling towers can be very effective at cooling water especially in areas of low humidity. Water can be cooled to within 5°C of the wet bulb temperature in a properly designed plant.

The most effective plants are fan forced and turn over a large store of water every hour. They operate overnight to cool a large volume of water, usually 4½ times the volume of the daily milk yield.

Ice banks

Ice banks generate ice along evaporator coils using night-rate power. The ice is used to chill water for the pre-cooler. The warm water is then returned from the pre-cooler to the top of the ice bank and cooled again as it runs down the ice.

If working on night electricity rates they may save money; ice banks take up less space than storage of chilled water.

Thermal stores

Thermal storage systems chill water using off-peak power and require an insulated storage tank to hold a large (one day’s milking) volume of chilled water. Using more energy than a direct expansion tank, they have advantages relating to installation and maintenance procedures.

Snap chillers

Another option is to use a refrigeration system to cool water or a food grade glycol/water mixture. Glycol systems tend to use a very small volume of fluid and chill the fluid on demand (at milking time).

Vat wraps

Vat wraps are only used by 20% of dairy farms in New Zealand but can save about 15-25% of milk cooling costs. They insulate milk from outside temperatures and weather, preventing it from heating up and reducing energy used by the refrigeration unit.

Effectiveness of a vat wrap will depend on whether your vat is inside or outside and where in NZ you are located.

Estimate savings from vat wrap installation and payback using the Energy Efficiency and Conservation Authority (EECA) calculator.