Amazone unveils flagship spreader

With the price of fertiliser still significantly higher than 2024, there is an increased onus on ensuring its spread accurately at the correct rate.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

Users will have more control during spraying operations with Amazone’s new DirectInject system.

It allows for the inclusion of supplementary crop protection products on the move while spraying.

Claas Harvest Centre Amazone product manager Joshua Patrick says farmers and contractors are constantly faced with new demands during spraying operations. As new products emerge and new technologies develop, farmers and contractors are increasingly asked to apply specific additional products, often to address a particular problem in a localised area of a paddock, or to refrain from spraying a specific product in environmentally-sensitive fields or bodies of water.

The DirectInject system allows the precise injection of specific products into the spray circuit, which can be stopped and started as required.

This means operators can now treat specific portions of the paddock with different agents, in just one pass – saving time and money.

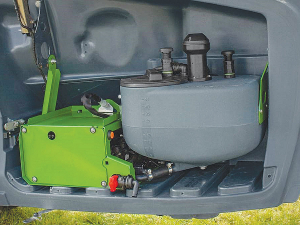

The system consists of an additional 50-litre tank built into the storage compartment located on the right-hand side of Amazone’s UX 01 Super trailed spray unit. Easily filled from ground level, the tank is fitted with its own metering system and incorporates a mechanical agitator to keep the blend homogenous.

The DirectInject feed system can be used with UX 01 single-axle crop protection sprayers fitted with the AmaSwitch or AmaSelect single nozzle control and DUS pro high-pressure recirculation system.

It is activated from the cabin at the touch of a button as operators detect specific weeds that need to be controlled using the supplementary product. The layout of the system keeps the pre-mixed spray agent from the main tank separate from the supplementary plant product by using a second spray line across the boom.

Circulation of the main line is stopped when the secondary direct feed is activated, so product from the main tank is not mixed with the product from the secondary tank.

DirectInject can work with undiluted plant protection agents, allowing unused quantities to be returned to the original container.

DairyNZ Chair Tracy Brown has seen a lot of change since she first started out in the dairy sector, with around one-third of dairy farmers now women.

Castle Ridge Station has been named the Regional Supreme Winner at the Canterbury Ballance Farm Environment Awards.

The South Island Dairy Event has announced Jessica Findlay as the recipient of the BrightSIDE Scholarship Programme, recognising her commitment to furthering her education and future career in the New Zealand dairy industry.

New Zealand and Chile have signed a new arrangement designed to boost agricultural cooperation and drive sector success.

New DairyNZ research will help farmers mitigate the impacts of heat stress on herds in high-risk regions of the country.

Budou are being picked now in Bridge Pā, the most intense and exciting time of the year for the Greencollar team – and the harvest of the finest eating grapes is weeks earlier than expected.

OPINION: A mate of yours truly reckons rural Manawatu families are the latest to suffer under what he calls the…

OPINION: If old Winston Peters thinks building trade relations with new nations, such as India, isn't a necessary investment in…