The key to a dairy system that generates high profit with a low emissions intensity is using low footprint feed, says Fonterra program manager on-farm excellence, Louise Cook.

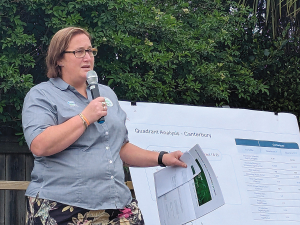

Cook spoke at the recent Lincoln University Dairy Farm (LUDF) spring focus day, where she outlined the Emissions and Profitability Project, a collaboration between Fonterra, DairyNZ's Dairybase and LIC.

The project analysed financials, physical farm characteristics and animal information data from 8000 farms over the last four seasons, combined into an anonymised database "of unprecedented scale".

While the analysis concentrated on Waikato and Canterbury because of the wealth of data from those provinces, it found similar results elsewhere.

Cook said one of the most interesting findings was that there's no relationship between emissions and profitability, so a high profitability farm could have low emissions intensity.

"But what we did find is when we looked at the data was that high profitability and low emissions intensity - that 'Golden Circle' - occurs when farmers have the majority of their feed coming from low footprint feed sources."

Cook said low footprint feed was first and foremost homegrown feed, grown and eaten on the dairy platform, but it also included comparably-produced feeds bought in or winter grazed off farm.

All other feeds would be considered high or very high footprint category, she said.

"What we saw is that farms that were low emissions intensity and high profitability, they had low footprint feeds as the majority of their diet."

Those farms were also doing well in productivity as measured in milksolids per cow or per kilo of live weight, although not necessarily exceptionally well.

The study divided farms into four quadrants, depending on whether they were high or low profitability, and high or low emissions intensity.

Comparing the high-profit/low-emissions farms (Q1) with high-profit/high-emissions farms (Q2) showed that Q1 farms achieved equal, and in some cases, slightly higher profitability.

The specific figures for the Canterbury farms in the study showed Q1 with emissions intensity of 9.31kg CO2/kg MS - 12% lower than Q2's 10.58kg.

There were no significant differences between Q1 and Q2 on most other metrics, including absolute emissions, operating profit, total feed eaten, stocking rates and production.

But there were significant differences between them in homegrown feed eaten, which came to 15.7 tDM/ha for Q2 compared with 16.3 tDM/ha for Q1; and in purchased N surplus - 130 kgN/ha for Q2 compared with 112 for Q1.

"What's interesting is in these Q1 farms, 1.8% of all feed eaten is high emissions footprint. In Q2, 8% of all feed eaten is high emissions footprint," said Cook.

"So, there's a really big difference there. Not only in the amount of supplement but also the type of supplement being brought in.”

Another finding was that the high profit low emissions intensity farms could be anywhere, and Cook presented a map of Canterbury showing quadrant 1 farms spread evenly across the whole province. She said she had met Culverden farmers who were firmly convinced those farms could only be in mid-central Canterbury because it had more growing days and more reliable irrigation, but the study showed that was not the case.

|

|---|

|

Russ Young, speaking at the LUDF Focus Day as part of a panel discussion of farmers with a record of high homegrown feed use.

|

“So, whilst we talk about homegrown feed being vital, you don’t have to have the highest homegrown feed, you just have to be a farm that’s making sure all of the feed you’re bringing in is actually really converting itself through into milk and product, and there’s a huge range in what we see there.”

Cook said the study arose out of Fonterra’s ambitions to lower emissions.

She said while there was “a whole bunch of stuff” known to reduce emissions intensity by increasing milksolids per cow – such as simply buying in more feed – farmers questioned whether that could risk their profitability.

However, Fonterra did not have a good link through to that financial information.

Homegrown Feed

The Focus Day also heard from a panel of three Canterbury farmers each with a record of higher reliance on homegrown feed.

Panellist Russ Young, the regional manager for Southern Pastures with responsibility for the group’s nine Canterbury farms, said that being asked to speak about homegrown feed was “no surprise”.

“It’s something we measure every year.”

Young said they measure all the feed that comes into the farms and the milk that goes out, also calculating and monitoring how much grass is grown, down to individual paddock level.

The panellists agreed on the use of custom spreadsheets to help keep track of all farm data, and good communication with all team members to keep farm goals in sight.