Renowned as market leaders in the self-propelled forage harvester sector, Claas has used its experience of chopping a wide range of crops on farms worldwide to improve the heart of the machine – the chopping cylinder.

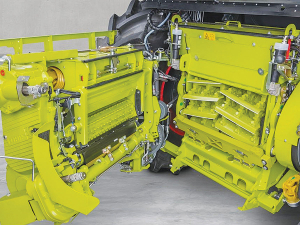

The new cylinder, known as V-Flex, claims to mark a new milestone in chopping cylinder technology.

Initially available on 900 and 900 Terra Trac Series machines as an alternative option to the V-Classic and V-Max cylinders, it is said to offer greater versatility when it comes to knife configuration. In combination with the new knives that it comes equipped with, Claas maintains that it has set new standards for smooth running and knife service life and enhanced chopping quality.

The new design enables higher throughputs, reduces noise levels and ensures smoother running with more consistent crop flow, especially for chop lengths over 12mm. The V-FLEX chopping cylinder is available in four versions, using 20, 24, 28 or 36 knives and can be configured as a full set of knives, half or one third the number of knives, to extend the length of cut, from 3.5 to 53mm.

High knife stability and the triple bolt fastening offers high knife stability, while also allowing the clearance between the cylinder and the shear bar to be reduced to achieve better chopping quality.

Meanwhile, Claas has also reconfigured the knife sharpening operation to make it more user-friendly with the control options for sharpening and shear bar adjustment, able be combined, with the cycle reduced to around one minute. The improvements are said to deliver greater efficiency with further reductions in fuel consumption per tonne of throughput.

Read More