Waikato dairy effluent breaches lead to $108,000 in fines

Two farmers and two farming companies were recently convicted and fined a total of $108,000 for environmental offending.

Irish slurry handling specialist Abbey Machinery is working to get more value from slurry. Business development manager international, Michael O’Grady explains.

As animals digest ingested feeds it is partitioned to maintenance, animal output (milk yield and constituents, live weight gain etc) and reproduction. The undigested portion passes out in their faeces.

Chopping and mixing feeds (protein, energy, minerals, fibre and water), even as part of a complementary buffer feed, helps the animal to digest the maximum amount of nutrients from the feeds to drive performance and reduce environmental emissions, from both nitrogen and methane.

Typically, waste materials are increasingly stored on-farm and applied to ground in a sustainable and environmentally friendly manner. Farm dairy effluent flow rates of around 50L/cow/day are typical (range from 20-115), with total solids of 0.5kg/cow/day (range from 0.5-0.95); with average total nitrogen of 22 g/cow/day (range 6-40) and the of total phosphorus of 2.5g/cow per day (range 1-6) (ref Heubeck, Nagels and Craggs, NIWA).

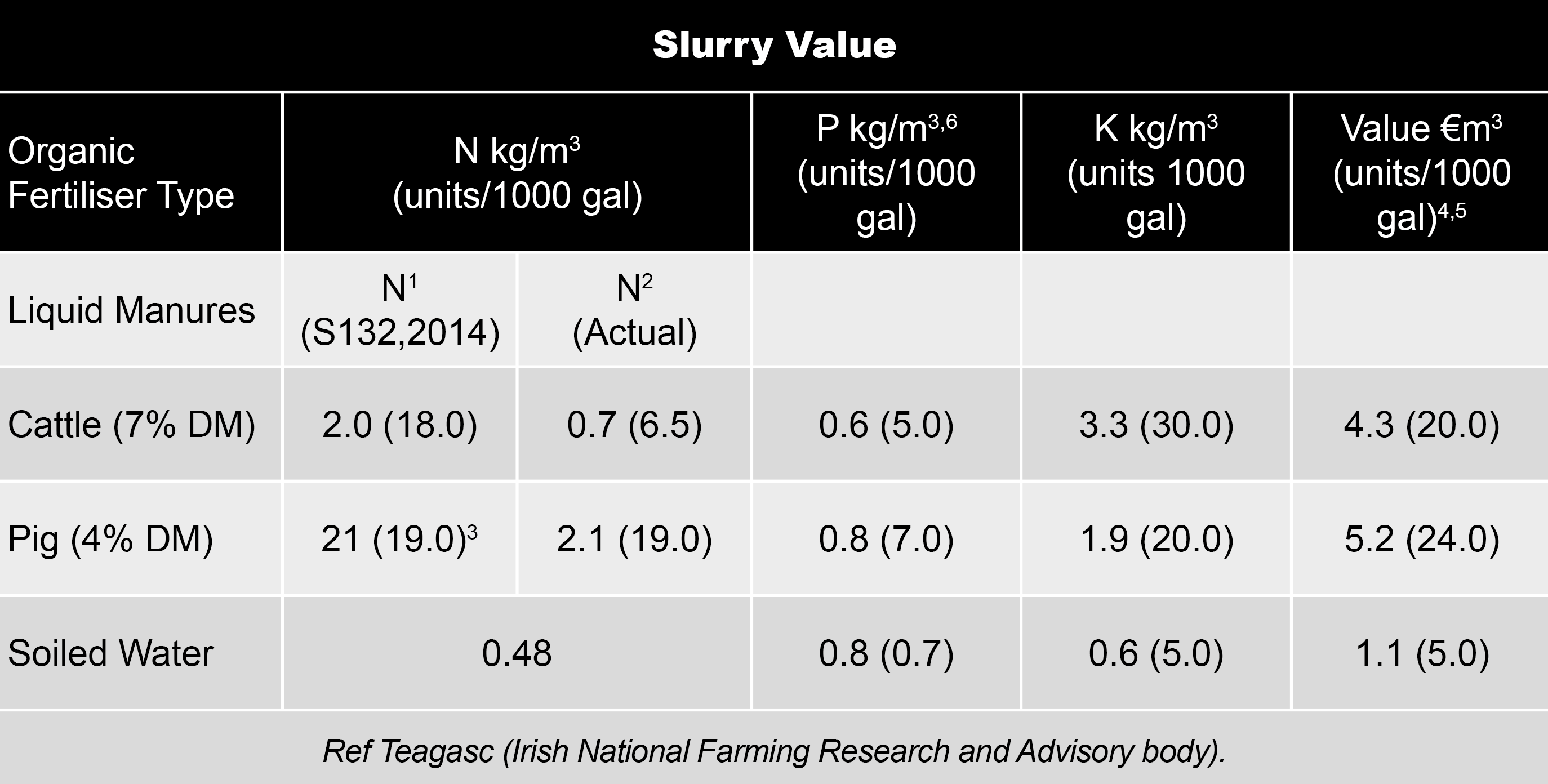

Slurry has a high fertiliser value. When applied in a timely manner, at the correct levels, it can help reduce purchased fertiliser bills on farm, add important organic matter back to the soil and improve pasture and livestock performance

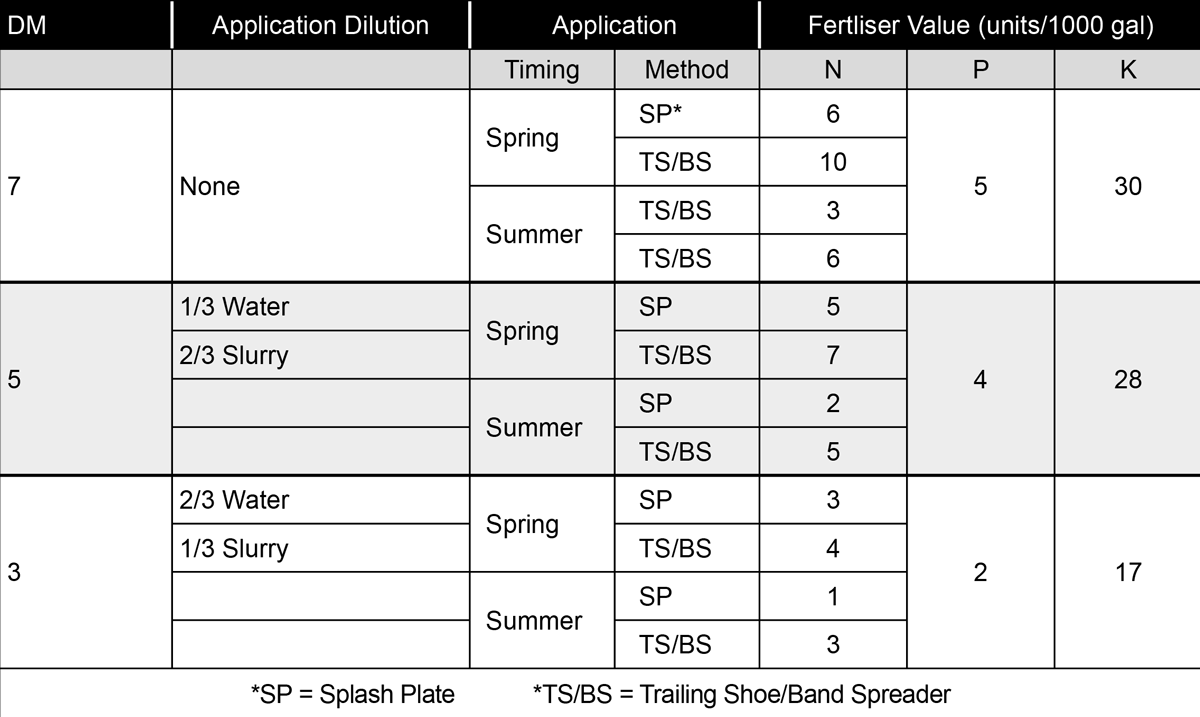

Phosphorus tends to be twice the value of potash and nitrogen. The full fertiliser value depends on the amount of nutrients available for plant uptake at time of slurry application and weather conditions at the time of application. Applications in the cool moist weather during spring, rather than summer, increases the amount of ammonium-N that is captured by the crop and reduces losses of N resulting from ammonia volatilisation.

The method of application also has a major bearing on utilisation, as seen when applying slurry below the crop canopy with a vertical trailing shoe. That allows grass to harness more of the ammonia and reduce volatilisation.

Irish slurry handling specialist Abbey Machinery is currently working on the live sensing of the N, P, K and AM levels in slurry during application through NIR, a process that will allow true precision slurry application.

In April 2019, Teagasc carried out field trials at its environmental research farm in Ireland comparing slurry applied by traditional splash plate and slurry applied using Abbey Machinery’s vertical trailing shoe applicator, at a rate of 3375L/ha. Applied on April 23, the trial plots were re-assessed on May 21 with yields being measured. The area applied by splash plate had 1200kg DM/ha, while the section applied with Abbey’s vertical trailing shoe had 2285kg DM/ha.

The 90% increase in grass yield from the same slurry, applied on the same day, gave a compelling argument towards the use of Abbey’s vertical trailing shoe.

New thinking on slurry application post silage cutting now recommends allowing the grass to re-grow, post-cutting for two weeks, then applying the slurry via vertical trailing shoe. In this way the grass is not contaminated with the slurry and the longer grass better harnesses the ammonia and maximises the nitrogen retention within the crop -- a win-win for the farmer and the environment.

The benefits of Abbey Machinery’s low emission slurry spreading equipment, DM band spreader, vertical trailing shoe or Tri-App trailing shoe and disc injector is how and where they deliver the slurry onto the soil to harness more fertiliser value, shorten rotation length, reduce carbon emissions.

They also allow the minimisation of crop contamination, reduce smell/odours and reduce fertiliser bills.

• Michael O’Grady is business development manager international for Abbey Machinery, Ireland.

Mating wrapped up last month at the across-breed Beef Progeny Test on Pāmu’s Kepler Farm in Manapouri.

Libby Judson is a keeper of memories from an age gone by. Tim Fulton tells her story.

A New Zealand-first native tree study has highlighted the Bioeconomy Science Institute's position as a forestry research leader.

Hemp fibre processor Rubisco is relocating its core processing facility to Ashburton as part of a $20-$30 million expansion to leverage what it says is an accelerating global demand for sustainable and renewable fibres.

Tradition meets some of the latest in technology at the 2026 East Coast Farming Expo.

OPINION: Trade Minister Todd McClay and the trade negotiator in government have presented Kiwis with an amazing gift for 2026 - a long awaited and critical free trade deal with India.

President Donald Trump’s decision to impose tariffs on imports into the US is doing good things for global trade, according…

Seen a giant cheese roll rolling along Southland’s roads?